Where should I put my 80gal Air Compressor?

#1

Senior Member

SuperSport

Thread Starter

Join Date: Jun 2010

Location: Baltimore, Maryland

Posts: 636

Where should I put my 80gal Air Compressor?

I going to hook up my compressor and wanted to ask everyone's opinion on where I should put it.

My two options are:

#1. Somewhere in the garage, most likely all the way in the corner;

#2. Down under the back porch, where there is an existing 220w plug;

Someone told me it's really really nice having the compressor somewhere other than you workspace (garage) so I'm leaning towards putting it under the porch. That would mean running air lines (PVC?) through cinderblock into the basement then through another block wall into the garage, maybe 20-30 feet to get it into the garage.

If it's under the porch it's a little more exposed to the elements, so I would build some type of enclosure to try and keep the weather out.

Are there any reasons under the porch would be a bad idea?

Is there anything else I'm not thinking about or missing?

This is my first time hooking up a large air supply system. I'm excited to be able to actually use our air tools. The current 20gal can't run my cut off wheel more than a few seconds.

My two options are:

#1. Somewhere in the garage, most likely all the way in the corner;

#2. Down under the back porch, where there is an existing 220w plug;

Someone told me it's really really nice having the compressor somewhere other than you workspace (garage) so I'm leaning towards putting it under the porch. That would mean running air lines (PVC?) through cinderblock into the basement then through another block wall into the garage, maybe 20-30 feet to get it into the garage.

If it's under the porch it's a little more exposed to the elements, so I would build some type of enclosure to try and keep the weather out.

Are there any reasons under the porch would be a bad idea?

Is there anything else I'm not thinking about or missing?

This is my first time hooking up a large air supply system. I'm excited to be able to actually use our air tools. The current 20gal can't run my cut off wheel more than a few seconds.

#5

The big downside of having it outside is that if you live somewhere that the temperature changes alot (freezie/thaw), you'll find alot of water in the tank and you'll be draining it alot. Water separators work well, but won't stop the buildup of water in the tank. Its a good idea if possible to have your compressor mounted high(near the ceiling) and have lines coming down from it, to wall mounted fittings with a 12" extension below them to trap water and give you the ability to drain the lines properly. I'll shoot some pictures of how I have mine setup in my shop to give you an idea of what I mean when I get home from work.

#6

A buddy of mine has his in the attic area of his garage. If that is an option, maybe look into it. Quiter than in being in the room. Easy to run lines to where you want and then drop them down.

#10

At the 10 bay school shop where I taught for 34 years, we had a huge 200 gallon 3 phase compressor that we moved outside, due to the noise, and built a shed around it. Hardly heard it cycle on then.

If you put it under the porch, how close are your neighbors? You'd have to shield it from weather and insulate for noise, but that shouldn't be a problem.

If you leave it in the garage, get some good earplugs. I've had tinnitus 24/7 for the last 10+ years.

If you put it under the porch, how close are your neighbors? You'd have to shield it from weather and insulate for noise, but that shouldn't be a problem.

If you leave it in the garage, get some good earplugs. I've had tinnitus 24/7 for the last 10+ years.

#11

So i snapped some photos of my setup, bear with me, my shop is a total disaster area....all of the crap from our renos still hasnt been cleaned out yet, so it looks like **** in there

First pic is how the compressor is mounted, simple steel pipe frame, rubber isolators on the feet...got it up there with a winch hooked on an eyelet on the ceiling.

Next is how the lines are run, I used 1" black pipe for mine...overkill yes...but it makes for alot more air volume in the system, and no restrictions. It will run a 3/4" impact gun, die grinders, cutoffs and not even break a sweat. (For example..I can remove 20 lugnuts and get 5 or 6 back on before it'll cycle) The extension pipe traps the water, so i just uncap and give the valve a quick blast to vent.

This pic gives you the whole idea of how my shop is plumbed. A main line runs around the shop with drops every 10 ft or so. Its way easier to put alot of drops in, then can work anywhere and not have to worry about hoses not reaching.

With the way its set up, I dont get very much moisture in the lines, the tank is up high, so draining it is a snap, and its off the floor and out of the way. One big thing to remember with compressed air systems is that if a line has to travel upwards, it will accumulate alot more moisture in it and that compressing air makes it hot, so if its outside it can build up more moisture during colder periods. One more thing....dont be scared to run higher pressure...you tools will work alot better, I run 140 psi, and every shop i've ever worked at does too.

I hope this helps you out!

First pic is how the compressor is mounted, simple steel pipe frame, rubber isolators on the feet...got it up there with a winch hooked on an eyelet on the ceiling.

Next is how the lines are run, I used 1" black pipe for mine...overkill yes...but it makes for alot more air volume in the system, and no restrictions. It will run a 3/4" impact gun, die grinders, cutoffs and not even break a sweat. (For example..I can remove 20 lugnuts and get 5 or 6 back on before it'll cycle) The extension pipe traps the water, so i just uncap and give the valve a quick blast to vent.

This pic gives you the whole idea of how my shop is plumbed. A main line runs around the shop with drops every 10 ft or so. Its way easier to put alot of drops in, then can work anywhere and not have to worry about hoses not reaching.

With the way its set up, I dont get very much moisture in the lines, the tank is up high, so draining it is a snap, and its off the floor and out of the way. One big thing to remember with compressed air systems is that if a line has to travel upwards, it will accumulate alot more moisture in it and that compressing air makes it hot, so if its outside it can build up more moisture during colder periods. One more thing....dont be scared to run higher pressure...you tools will work alot better, I run 140 psi, and every shop i've ever worked at does too.

I hope this helps you out!

#12

Porch, black steel pipe, not PVC. Plan your lifts, angles and a drain leg. Pop for a few $ and get an auto drain valve for the tank and drain the drain leg weekly. Consider a simple enclosure for the compressor, plywood and 2x4s works great. add a hings , latch and some paint for a better working / looking solution.. little bit of insulation and a baffled vent makes for happy wife, and folks that live close. As well as protects the compressor from out side elements.

#13

I agree with the last post in some ways with minor add ons. I did a large shop compressor adding the lines. Like he said, have drops on each connector like a T with the valve at 90 deg and a 6" capped nipple. Put a brass radiator drain in the cap to easliy drain the line on occasion. All lines down hill from the compressor as much as possible. Even if you go up to the ceiling run downhill slightly away from the compressor on the ceiling line. I'm liking the idea of either one of those trouble light type hose setups or just having a few lines dangling about six and a half feet off the floor in strategic positions. If anyone is in my garage that is over 6'6" they are at their own risk.

One addition is to extend your intake to an out of doors position, you could put a simple old car or bike air filter with the intake down on the end of it. That way you're drawing the coolest air under most circumstances with minimal moisture again in most cases. I remember the area of that huge old compressor would get seriously hot, so running the intake out side the building had to help.

One addition is to extend your intake to an out of doors position, you could put a simple old car or bike air filter with the intake down on the end of it. That way you're drawing the coolest air under most circumstances with minimal moisture again in most cases. I remember the area of that huge old compressor would get seriously hot, so running the intake out side the building had to help.

Last edited by klx678; 12-10-2011 at 05:40 AM.

#14

Senior Member

SuperSport

Thread Starter

Join Date: Jun 2010

Location: Baltimore, Maryland

Posts: 636

Thanks for all the responses and suggestions everyone!

Good point! I have some thick rubber I'll cut a few pads for the legs.

I wouldn't expect this comp. to run a full shop with a lot of bays. It just needs to run one tool at a time, so it will be plenty. With volume comes flow.

Our 25gal/4hp tank on wheels puts out 9CFM@40P.S.I and 7CFM@90P.S.I. The new one is a 220v two stage 80gal/5hp. Makes 13.5CFM@90psi and 12.5CFM@175psi!!!! It will be a much better working air supply. Our impact guns will actually be usable now! can't wait

We live on 25 acres so neighbors are a good distance away. I will be building an enclosure more for weather protection, but sound dampening will be a side bonus. I'm aware the perils of tinnitus, my father was a C130 pilot for 20 years and now flies for American Airlines, he has bad tinnitus, I've vowed to protect my ears so when I'm his age I don't say "what? What?" everytime someone talks to me. It's really annoying/frustrating repeating myself 3 times for everything I want to say.

How do I need to plan my lifts(what is lift) and angles? With the under-porch set up the tank will be one floor below the garage/work space. Is it a problem to run lines uphill to the garage? extra precautions or drains I need to figure in for that? How do different angles effect the moisture collection?

not sure exactly what you mean at the beginning, are you saying I should have a 6" drop with a water valve at each hose connections in the garage? What is the "trouble light type hose setup". You mean the wind up spring retracting hoses that coil up themselves? I planned to have at least one for quick pull down and take where you need it. Would it be best to run my main line up to the top of the garage, then downhill to all my connections?

The entire compressor will be outside, so the intake will too. I had thought to myself there would be MORE moisture in the air outside, and I was actually wondering if running the intake into the basement would be better, the air inside is dry, we always have the dehumidifier running in the basement.

Our 25gal/4hp tank on wheels puts out 9CFM@40P.S.I and 7CFM@90P.S.I. The new one is a 220v two stage 80gal/5hp. Makes 13.5CFM@90psi and 12.5CFM@175psi!!!! It will be a much better working air supply. Our impact guns will actually be usable now! can't wait

At the 10 bay school shop where I taught for 34 years, we had a huge 200 gallon 3 phase compressor that we moved outside, due to the noise, and built a shed around it. Hardly heard it cycle on then.

If you put it under the porch, how close are your neighbors? You'd have to shield it from weather and insulate for noise, but that shouldn't be a problem.

If you leave it in the garage, get some good earplugs. I've had tinnitus 24/7 for the last 10+ years.

If you put it under the porch, how close are your neighbors? You'd have to shield it from weather and insulate for noise, but that shouldn't be a problem.

If you leave it in the garage, get some good earplugs. I've had tinnitus 24/7 for the last 10+ years.

Porch, black steel pipe, not PVC. Plan your lifts, angles and a drain leg. Pop for a few $ and get an auto drain valve for the tank and drain the drain leg weekly. Consider a simple enclosure for the compressor, plywood and 2x4s works great. add a hings , latch and some paint for a better working / looking solution.. little bit of insulation and a baffled vent makes for happy wife, and folks that live close. As well as protects the compressor from out side elements.

I agree with the last post in some ways with minor add ons. I did a large shop compressor adding the lines. Like he said, have drops on each connector like a T with the valve at 90 deg and a 6" capped nipple. Put a brass radiator drain in the cap to easliy drain the line on occasion. All lines down hill from the compressor as much as possible. Even if you go up to the ceiling run downhill slightly away from the compressor on the ceiling line. I'm liking the idea of either one of those trouble light type hose setups or just having a few lines dangling about six and a half feet off the floor in strategic positions. If anyone is in my garage that is over 6'6" they are at their own risk.

not sure exactly what you mean at the beginning, are you saying I should have a 6" drop with a water valve at each hose connections in the garage? What is the "trouble light type hose setup". You mean the wind up spring retracting hoses that coil up themselves? I planned to have at least one for quick pull down and take where you need it. Would it be best to run my main line up to the top of the garage, then downhill to all my connections?

One addition is to extend your intake to an out of doors position, you could put a simple old car or bike air filter with the intake down on the end of it. That way you're drawing the coolest air under most circumstances with minimal moisture again in most cases. I remember the area of that huge old compressor would get seriously hot, so running the intake out side the building had to help.

#15

The air in a warmer area will hold more moisture than cooler air. When a compressor draws warm inside air that cools it will condense in the tank, thus usually the ouside air has less moisture. Even in the summer, unless you have air conditioning in the garage drying it out. It's all about where the draw would get the least moisture. In our case it was outside rather than inside. I built a box overtop the intake to keep out rain.

If you run the pipe to the ceiling area put a T at the point where it goes up, put the T in sideways so you have a drop of at least 6" directly below the pipe going up, with a drain. That is what the installers usually do on gas lines in houses, put a drop for moisture and such, if you look (but no drain, gas fume leakage, you have to turn off gas to take it off to drain if needed). You always prefer running down away from the compressor to get moisture to drip or run away from the tank. Doesn't have to be much, but it should be there.

I had a similar situation on my KLX that exhibits the concept. The KLX650C will drip oil from the air box. Bugged the heck out of me. Then when doing the valves I saw why... the breather tube runs downhill to the air box, thus any condensation goes to the air box. I put in a little PVC tube above the head with some coarse scrubbing pad material in it and fittings for the breather tube size. Now no drips. The mist goes up into the tube, some oil may condense as it passes through the steel wool, then a less dense air/oil mix goes to the intake. The air box will get a light coating of oil and the filter shows a spot above the breather vent, but there isn't enough oil condensation to even create a drop of oil out the drain now. Same works with a compressor, run down away from the compressor with any lines whenever possible.

Yes, the trouble light reference was referring to the deal you speak of. I just would more likely put three fitting drops from the ceiling since they'd be cheap to do and put a line where I'd want it. The only other thing that would be better would be some kind of boom like a car wash has, an air tight rotary fitting that allows the boom to swihg all around a vehicle. This would be best for painting for sure and also if you just don't want the hose draped on your vehicle. I'd do that before some coil deal just because it would be more value to me.

I know there are guys doing PVC for air, I don't know, but I'm guessing it's probably schedule 80. I don't know if the burst strength of schedule 40 is adequate with a measure of safety. Black pipe is absolutely functional in all instances when it comes to burst strength.

If you run the pipe to the ceiling area put a T at the point where it goes up, put the T in sideways so you have a drop of at least 6" directly below the pipe going up, with a drain. That is what the installers usually do on gas lines in houses, put a drop for moisture and such, if you look (but no drain, gas fume leakage, you have to turn off gas to take it off to drain if needed). You always prefer running down away from the compressor to get moisture to drip or run away from the tank. Doesn't have to be much, but it should be there.

I had a similar situation on my KLX that exhibits the concept. The KLX650C will drip oil from the air box. Bugged the heck out of me. Then when doing the valves I saw why... the breather tube runs downhill to the air box, thus any condensation goes to the air box. I put in a little PVC tube above the head with some coarse scrubbing pad material in it and fittings for the breather tube size. Now no drips. The mist goes up into the tube, some oil may condense as it passes through the steel wool, then a less dense air/oil mix goes to the intake. The air box will get a light coating of oil and the filter shows a spot above the breather vent, but there isn't enough oil condensation to even create a drop of oil out the drain now. Same works with a compressor, run down away from the compressor with any lines whenever possible.

Yes, the trouble light reference was referring to the deal you speak of. I just would more likely put three fitting drops from the ceiling since they'd be cheap to do and put a line where I'd want it. The only other thing that would be better would be some kind of boom like a car wash has, an air tight rotary fitting that allows the boom to swihg all around a vehicle. This would be best for painting for sure and also if you just don't want the hose draped on your vehicle. I'd do that before some coil deal just because it would be more value to me.

I know there are guys doing PVC for air, I don't know, but I'm guessing it's probably schedule 80. I don't know if the burst strength of schedule 40 is adequate with a measure of safety. Black pipe is absolutely functional in all instances when it comes to burst strength.

Last edited by klx678; 12-10-2011 at 08:32 AM.

#16

Senior Member

SuperSport

Thread Starter

Join Date: Jun 2010

Location: Baltimore, Maryland

Posts: 636

Yea, that makes sense about the cooler air having less moisure...and warmer/more humid air cooling in the tank forming condensation.

The only reason I was thinking PVC is it's cheaper, I'd imagine easier to work with, easier to assemble without leakage(A friend told me he had a hell of a time getting rid of all the leaks on his metal pipe system).

I would also think the metal being cooler would cause more condensation to build up? But I guess it's better for any water in the air to condense in the pipe as opposed to going through my tools.

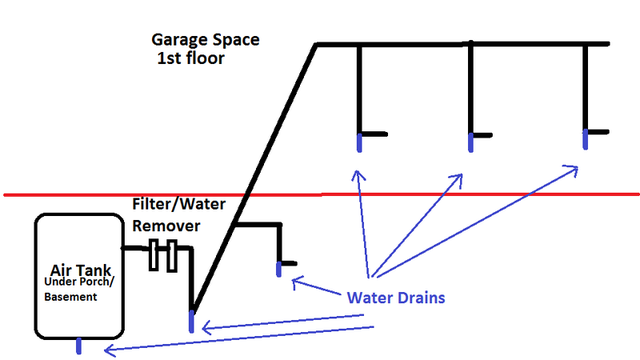

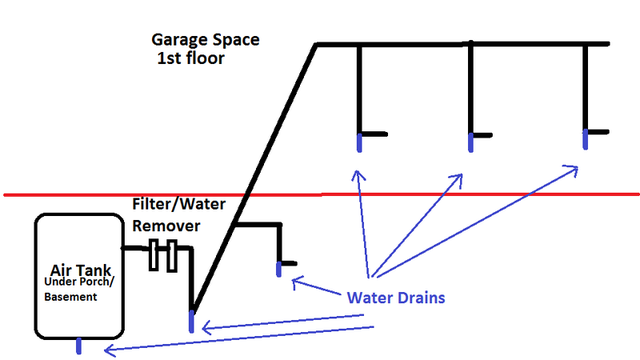

Here's a little diagram I made in paint, does this look like a good configuration for lines/water drains?

The only reason I was thinking PVC is it's cheaper, I'd imagine easier to work with, easier to assemble without leakage(A friend told me he had a hell of a time getting rid of all the leaks on his metal pipe system).

I would also think the metal being cooler would cause more condensation to build up? But I guess it's better for any water in the air to condense in the pipe as opposed to going through my tools.

Here's a little diagram I made in paint, does this look like a good configuration for lines/water drains?

Thread

Thread Starter

Forum

Replies

Last Post